Researchers Develop Autonomous Excavator System for “Unmanned” Excavation

[ad_1]

Researchers at the Baidu Research Robotics and Auto-Driving Lab (RAL) and the University of Maryland, College Park have introduced an Autonomous Excavator System (AES) that can perform material loading tasks for a long time without any human intervention while offering almost equivalent performance. to that of an experienced human operator.

AES is one of the world’s first unmanned excavation systems to be deployed in real-life scenarios and to operate continuously for over 24 hours, providing industry-leading benefits in terms of improved safety and productivity.

The researchers described their methodology in a research paper published on June 30, 2021 in Scientific robotics.

“This work presents an efficient, robust and general autonomous system architecture that enables excavators of various sizes to perform real-world material loading tasks autonomously,” said Dr Liangjun Zhang, corresponding author and director from Baidu Research Robotics and Auto-Driving Laboratory.

A scientific approach to robotics

Excavators are vital for infrastructure construction, mining and rescue applications. The global excavator market size was $ 44.12 billion in 2018 and is expected to reach $ 63.14 billion by 2026.

With this expected market increase, construction companies around the world are facing a shortage of hiring skilled heavy equipment operators, especially excavators. Additionally, COVID-19 continues to exacerbate the labor shortage crisis. Another contributing factor is the hazardous and toxic work environments that can impact the health and safety of human operators at the site, including collapses, ground collapses, or other excavation accidents which are around 200 victims per year in the United States alone.

The industry therefore takes a scientific approach and seeks to create robot excavators capable of providing revolutionary solutions to meet these needs, making the development of systems such as AES a growing trend alongside the implementation of other robots. in manufacturing, warehouses and autonomous vehicles.

While most industrial robots are comparatively smaller and operate in more predictable environments, robot excavators must operate in a wide range of hazardous environmental conditions. They must be able to identify target materials, avoid obstacles, handle uncontrollable environments and keep running in difficult weather conditions.

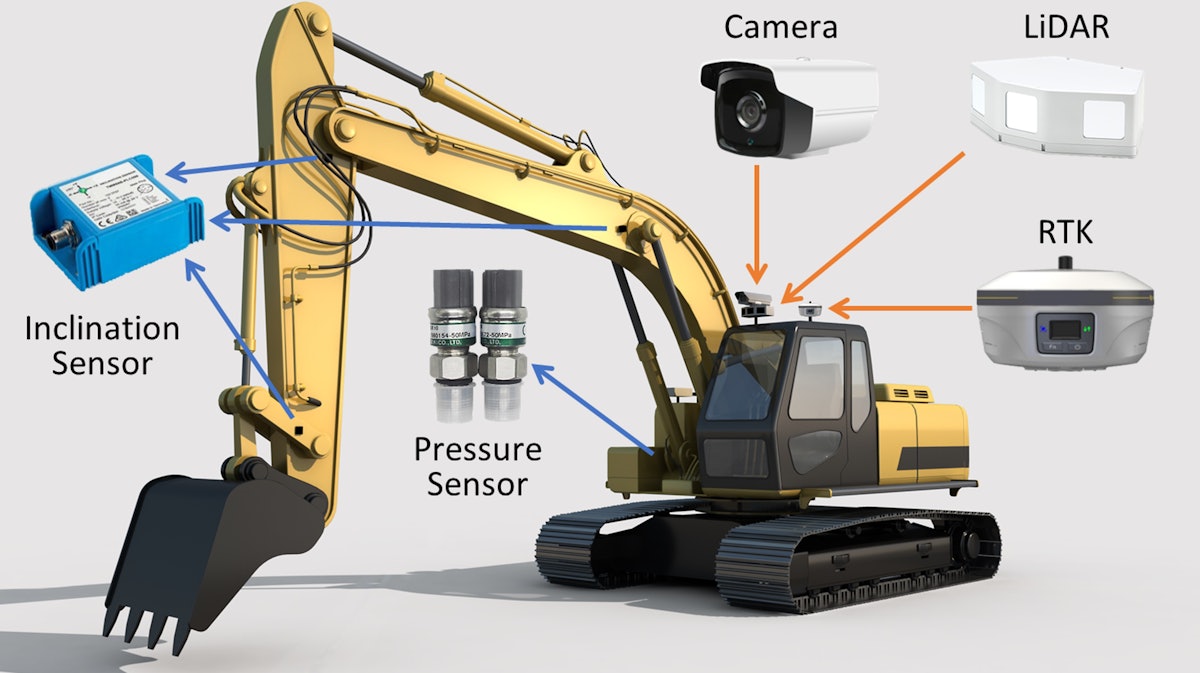

AES uses precise, real-time algorithms for perception, planning and control, as well as a new architecture to incorporate these capabilities for autonomous operation. Several sensors including LiDAR, cameras and proprioceptive sensors are integrated for the perception module to perceive the 3D environment and identify target materials, as well as advanced algorithms such as a dusting neural network to generate crisp images .

Thanks to this modular design, the AES architecture can be used efficiently by excavators of all sizes – including compact excavators of 6.5 and 7.5 tons, standard excavators of 33.5 tons and large excavators of 49 tonnes – and is suitable for various applications.

Team effort for testing

To assess the efficiency and robustness of the AES, the researchers partnered with a leading company in the manufacture of equipment to deploy the system to a waste disposal site, a real toxic and harmful scenario where the automation is in high demand. Despite the difficult mission, AES was able to operate continuously for over 24 hours without any human intervention. AES has also been tested in winter weather conditions, where vaporization can pose a threat to the detection performance of LiDAR. The amount of material excavated, both wet and dry, was 67.1 cubic meters per hour for a compact excavator, which matches the performance of a traditional human operator. “AES works consistently and reliably over a long period of time, while the performance of human operators can be uncertain,†said Dr. Zhang.

The researchers also set up ten different scenarios on a closed proving ground to see how the system performed in many real-world tasks. After testing a variety of large, medium and compact excavators, the AES was finally found to match the average efficiency of a human operator in terms of the amount of material excavated per hour.

“This represents a key step towards the deployment of robots with long periods of operation, even in uncontrolled indoor and outdoor environments,” said Dr Dinesh Manocha, distinguished university professor of computer science and electrical and computer engineering at University of Maryland, College Park.

Going forward, Baidu Research RAL will continue to refine the core AES modules and further explore scenarios where extreme weather or environmental conditions may be present.

Baidu has worked with several of the world’s largest construction machinery companies to automate traditional heavy construction machinery with AES. “We aim to leverage our robust and secure platform with our powerful AI and cloud capabilities to transform the construction industry,†said Dr. Haifeng Wang, CTO of Baidu.

[ad_2]